| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SBN |

| Model Number : | SLG 95 SLG 120 |

| Certification : | CE ISO BV SGS |

| Price : | 30000 |

| Supply Ability : | 3 sets per month |

| Delivery Time : | 30-60 days |

Fully Automatic Pet Food Production Equipment

1.Product information of Pet Food Production Equipment

Base on the market demand,to do R&D of Fully Automatic Pet Food

Production Equipment for various models and settings.By adjusting

raw materials,temperature,moisture and other technical parameters,

to make our products with characteristics of unique shape, elegant

texture, plenty of nutrients, suitable for the usage of different

kinds of dog. Furthermore, Fully Automatic Pet Food Production

Equipment can be widely used to produce dog, cat, shrimp, fox,bird

and pet food production.

2.Fully Automatic Pet Food Production Equipment process flow:

Raw material preparation→Mixing raw

material→Conveying→Extrusion→Conveying→Drying→Screening→Oil

spraying→Flavoring→Packing

3.Fully Automatic Pet Food Production Equipment specifications:

| Model | Installed power | Real power | Output | Dimension |

| SLG65 | 70kw | 40kw | 100-150kg/h | 22000*1200*2200mm |

| SLG70 | 90kw | 50kw | 200-240kg/h | 25000*1500*2200mm |

| SLG85 | 120kw | 100kw | 400-500kg/h | 30000*3500*4300mm |

| SLG90 | 135kw | 100kw | 800-1200kg/h | 30000*3500*4300mm |

| SLG120 | 215kw | 150kw | 2000-3000kg/h | 30000*3500*4300mm |

4.Formation of Fully Automatic Pet Food Production Equipment:

1 Mixer:There are 3 machine model numbers to choose from base on

the production capacity.

2 Conveyor:To convey raw materials to the extruder machine

3 Extruder machine: To choose DSE model extruders base on the

production capacity requirement from 100kg per hour to 3ton per

hour. The raw material include corn powder, cereal powder, soybean

powder, shrimp powder and so on. Shape of the pellet depends on the

moulds.

4 Hoister: Convey the dog food to the dryer, the height of the

hoister depends on the dryer.

5 Multilayer dryer:Electric dryer, controlled by control box,

temperature range 0-200ºC.Inside is stainless steel double layer

mesh net. Drying time is adjustable according to speed. We have

dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5

layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6 Sifter:To remove scrap

7 Flavoring line: To spray oil and phagostimulant, the equipment

are: single roller, double roller, round roller, eight-angle

roller. Varies depends on the different production line setting, to

spray oil to the surface of the product and make it even.

8 Cooling conveyor: To lower the product temperature in order to

pack it easily.

9 Sifter: To remove the wasted material and ensure quality,

meanwhile to ensure the reuse of materials.

10 Packing machine: Manual and automatic packing machine.

7.Our wide product range:

For now, our main products are Food Twin Screw extruder, Feed Twin

Screw extruder, Fish food machine, Dog Food machine, Pet Cat Food

machine, Doritos Tortilla chips machine, Nik naks Kurkure Cheetos

machine, Modified starch machine, Corn flakes machine, Corn puffs

Cheese ball machine, Frying pellets machine, Artificial rice Puffed

rice machine; Core filling Pillow Tube Finger snack machine;

Vertical Packaging machine, Flowpack packaging machine. Our Feed

Extruder for Fish Dog Cat Main Market is Africa(like Nigeria,

Uganda); Asia(Like Turkey, Uzbekistan, Iran, India, Indonesia,

Thailand, Malaysia); Oceania(Australia); North America(Canada);

Central America & South America(like Mexico, Venezuela, Costa Rica,

Latvia, Brazil, Peru, Uruguay, Paraguay, Chile, Argentina)

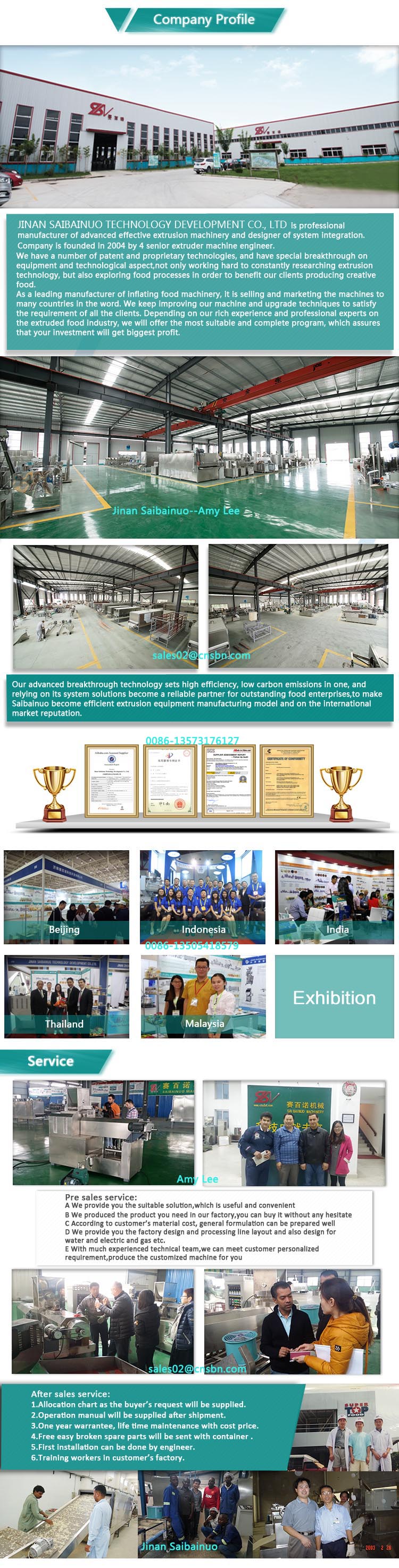

8. Exhibition:

We take part in exhibition in many countries like Turkey, Iran,

Brazil, Mexico, Beijing, Shanghai and we are also still continuing.

I am looking forward to seeing you and talking with you on the fair

in near future.

Customer visiting & about me:

We sincerely welcome you and your team visit our factory, it will

be highly appreciated if you can bring sample to us, we will let

our technician test machine for you accordingly.

Any inquiry or Interests, Please feel free to contact me or

whatsapp or leave me message

FAQ

1. Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has almost 10 years of experience

in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can get a

flight to Jinan Airport. Our factories are just about 30 minutes

drive away from Jinan Airport.We are so glad to arrange our car

pick you up!

3. Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives the customer's

side.).

After this period we will definitely support you when needed.

You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer.

Or you can get local contractors to do the commissioning and we

send one supervising engineer.

Service

Our Services Our wooden packing for exporting level before

delivery:

Our engineer would go to buyers place to installing the machinery

to buyers.After the machinery arrived at buyers place .

1). At least 1 year from the date of completion of the

commissioning.

2). Free consultation service before, during, and after sales;

3). Free project planning and design services;

4). Free debugging of equipment until everything is functional;

5). Free management of equipments long distance shipping;

6). Free training of equipment maintenance and operating

personally;

7). Free new production techniques and formulas;

8). Provide 1 year complete warranty and life-time maintenance

service;

Please contact me for more information, welcome to visit our factory!

|